Patented Screws in 2025 - A New Era of High Efficiency, Sustainability, and Structural Safety

In 2025, the construction industry faces mounting pressure to deliver buildings faster, greener, and safer. Developers, contractors, and engineers demand solutions that accelerate installation, lower environmental impact, and uphold structural integrity over decades. Among the unsung heroes in this leap forward are patented screws—engineered fasteners designed to meet precisely those three imperatives. In this article, we unpack how the next generation of patented screws is rising to the challenge and present real-world product examples to illustrate how they deliver on efficiency, sustainability, and safety.

What Are Patented Screws?

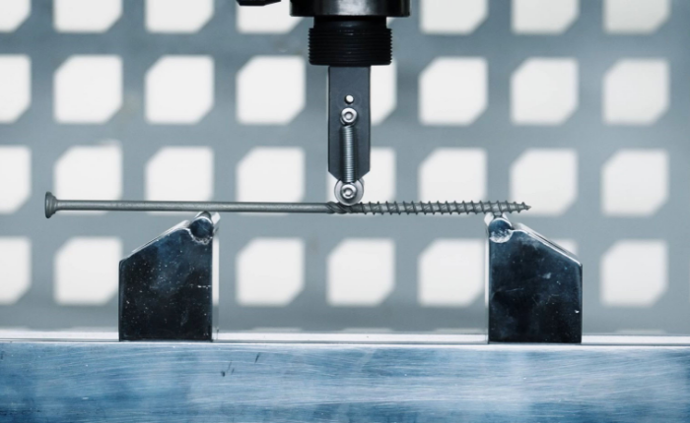

“Patented screws” refers to screw designs protected by intellectual property rights that incorporate special geometries, materials, coatings, or drive systems—beyond generic standards—to deliver enhanced performance in construction contexts.

Key features that often distinguish patented screws include:

-

Advanced tip or point geometries (self-drilling, arrow tips)

-

Unique thread profiles (twister threads, variable pitch, anti-split designs)

-

Optimized drive recesses (hex-star, Torx, specialized heads)

-

Multi-material compatibility (metal-to-wood, composite boards, fiber cement)

-

Corrosion-resistant surface treatments engineered for durability

These features are not just niceties—they address real constraints on the construction site: torque control, drilling speed, substrate variation, splitting risks, fastening in composite assemblies, and long-term durability under weather cycles.

Differences Between Patented Screws and Ordinary Screws

To understand why patented variants matter, consider how they outstrip commodity screws along three axes that matter most to construction:

| Criterion | Ordinary Screws | Patented Screws |

|---|---|---|

| Installation Speed | Often require pre-drilling, multiple steps, or pilot holes | Advanced tip geometry and cutting flutes reduce or eliminate pre-drilling, saving labor |

| Drive Efficiency | Higher torque, risk of cam-out, inefficient power tool cycles | Low-torque threads and optimized recesses lower tool energy and reduce fatigue |

| Holding & Withdrawal Strength | Standard thread engagement, risk of pull-out or loosening | Specialized threads and anti-split designs improve grip and durability |

| Substrate Versatility | May perform well only in wood or metal, but poorly in composites or fiber cement | Engineered for multi-material compatibility (wood, OSB, steel, fiber cement) |

| Durability / Corrosion Resistance | Basic galvanizing or zinc plating with limited longevity | Enhanced coatings (Geomet, e-coatings, advanced passivation) matched to environmental demands |

| Safety Margin | Greater variability in performance tolerances | Tighter tolerances, better testing, and safer margins under load & fatigue cycles |

In short: patented screws convert design investment into on-site performance gains—less rework, faster cycles, and greater long-term reliability.

Case Examples of Patented Screw Solutions

Here are five patented screw designs from Fong Prean that illustrate how advanced fasteners can respond to the construction industry’s demands for efficiency, sustainability, and structural safety:

| Patented Screw | Key Advantages / Patented Features | Application Notes |

|---|---|---|

| 3IN1 Multi-Function Clip Screw | This “3-in-1” screw combines Hex-Star recess, Twister thread, and Arrowy point into a composite design. It offers low drive torque, high pull-out strength, and fast penetration across metal, wood, OSB, and plywood substrates. | Ideal for standing-seam roof clips, metal-to-wood or composite fastenings — useful where a single screw must cope with mixed materials. |

| Arrowy® Collated (Plasterboard) Screw | The Arrowy® series features a sharp, high-penetration tip (the “Arrowy” point) and powerful thread geometry to reduce installation time and improve holding power. Fong Prean positions it as faster, more stable, and more cost-effective than wing-type or traditional drywall screws. | Best used for drywall (plasterboard) to wood or light steel applications, especially in collated (automated) screw gun workflows. |

| Countersunk 12-V-Ribs Head Fiber Cement Board Screw | A distinctive patented 12-V-Ribs geometry under the head allows the screw to seat smoothly and flush on fiber cement board surfaces, delivering a burr-free finish. Also includes drill-point options (some with wings) to reduce or eliminate pre-drilling. | Designed for fastening fiber cement panels (backer board) to wood or light-gauge steel frames, especially where surface appearance and clean countersinking matter. |

| MS Reamer Hardwood (IPE Deck) Screw | This screw integrates a special Reamer thread and sharp point that allow direct penetration into dense hardwoods (e.g. IPE) without pre-drilling. The Magic Spiral head likewise aims to produce a clean, flush, burr-free finish. | Excellent for hardwood decking, premium timber applications, or hard-board insertions — any scenario where pre-drilling would slow the workflow or risk splitting. |

| MS Twister Timber / Wood Screw | The Twister design emphasizes low driving torque and high holding power. Its patented spiral countersunk head ensures flush seating without burrs or mushrooming. Fong Prean claims it can raise work efficiency by up to 60% and reduce splitting even when close to board edges. | Suited for general wood joinery, furniture, interior finishes, or any application where installer fatigue, clean finish, and splitting control are key concerns. |

Conclusion

In 2025 construction landscape, the triad of efficiency, sustainability, and structural safety is nonnegotiable. Patented screws are no longer niche peripherals—they are core components that help the industry meet higher standards without compromising timelines or budgets.

-

They reduce labor and cycle time via optimized tips and threads.

-

They help projects comply with green building mandates by reducing waste, enabling disassembly or reuse, and extending durability.

-

They raise safety margins through better material matching, refined tolerances, and stronger load performance.

For specifiers, architects, contractors, and product managers, the shift is clear: evaluate fasteners not only by price, but by lifecycle value. Integrating patented screws into your procurement and design workflows can translate into fewer punch-list issues, better long-term performance, and competitive differentiation in the marketplace.